When it comes to heavy machinery, precision and reliability are paramount. Caterpillar, a name synonymous with high-quality construction and mining equipment, understands this better than anyone. To ensure that their equipment operates smoothly and efficiently, Caterpillar provides detailed parts book manuals. These manuals are invaluable resources that illustrate how each component fits together with the help of exploded diagrams. This article delves into the various aspects of the Caterpillar parts book manual, offering insights into its detailed breakdown, the role of exploded diagrams, understanding component interactions, and navigating the comprehensive manual.

Detailed Breakdown of Caterpillar Parts Book Manual

The Caterpillar parts book manual is an extensive resource that provides a detailed breakdown of every component within a Caterpillar machine. It covers everything from the smallest screws to the largest engine parts, ensuring that users can find the exact information they need for maintenance and repairs. Each section of the manual is meticulously organized, allowing users to quickly locate the parts they are interested in.

This manual is not just a simple list of parts; it includes detailed descriptions and specifications for each component. This ensures that users know exactly what they are looking at and can make informed decisions when ordering replacement parts or performing maintenance. The descriptions often include material specifications, dimensions, and other critical details that are essential for ensuring compatibility and performance.

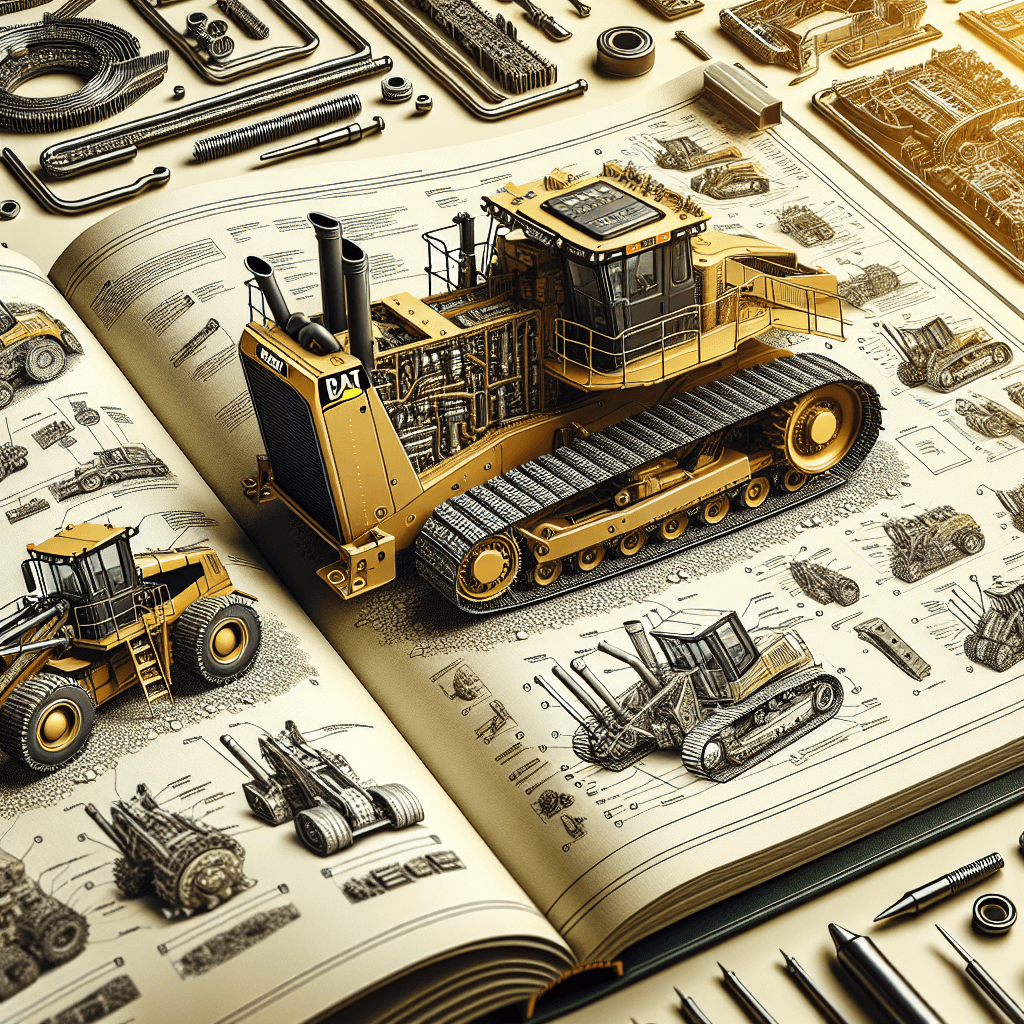

One of the standout features of the Caterpillar parts book manual is its use of exploded diagrams. These diagrams provide a visual representation of how each component fits together, making it easier for users to understand the assembly process. Each part is labeled with a unique identifier, which corresponds to a detailed description in the manual. This makes it easy to cross-reference parts and ensure that everything is assembled correctly.

The manual also includes detailed maintenance schedules and procedures, ensuring that users can keep their equipment in top condition. This includes recommended service intervals, lubrication points, and other critical maintenance tasks. By following these guidelines, users can extend the life of their equipment and reduce the risk of unexpected breakdowns.

For those who need to order replacement parts, the manual includes detailed ordering information. This includes part numbers, descriptions, and pricing information, making it easy to order the correct parts. Many manuals also include information on authorized dealers and service centers, ensuring that users can get the support they need when they need it.

Overall, the Caterpillar parts book manual is an invaluable resource for anyone who owns or operates Caterpillar equipment. Whether you are performing routine maintenance or undertaking major repairs, this manual provides the detailed information you need to get the job done right.

Exploded Diagrams: A Visual Guide to Assembly

Exploded diagrams are a cornerstone of the Caterpillar parts book manual. These diagrams provide a visual representation of how each component fits together, making it easier for users to understand the assembly process. Each part is shown in its relative position, with lines indicating how they connect to one another. This visual guide is especially useful for complex assemblies where the relationship between parts may not be immediately obvious.

The use of exploded diagrams in the Caterpillar parts book manual offers several advantages. First and foremost, it provides a clear and concise way to understand the assembly process. Instead of relying solely on written descriptions, users can see exactly how parts fit together, which reduces the likelihood of errors during assembly. This is particularly important for intricate systems where even a small mistake can lead to significant issues.

Another advantage of exploded diagrams is that they make it easier to identify individual parts. Each component is labeled with a unique identifier, which corresponds to a detailed description in the manual. This makes it easy to cross-reference parts and ensure that everything is assembled correctly. Users can quickly locate the part they need and see how it fits into the larger assembly, which streamlines the repair and maintenance process.

Exploded diagrams also provide a valuable reference for troubleshooting. When a machine is not functioning correctly, these diagrams can help users identify which components may be causing the issue. By visually tracing the assembly, users can pinpoint potential problem areas and take corrective action. This can save time and reduce the need for trial-and-error troubleshooting.

For those who are new to working with Caterpillar equipment, exploded diagrams provide a helpful learning tool. They offer a clear and intuitive way to understand the complex relationships between different parts. This can be especially beneficial for training new employees or for users who are not familiar with a particular piece of equipment.

Overall, exploded diagrams are an essential feature of the Caterpillar parts book manual. They provide a clear, visual guide to assembly, making it easier for users to understand how each component fits together. Whether you are performing routine maintenance or undertaking a major repair, these diagrams provide the detailed information you need to get the job done right.

Understanding How Every Component Fits Together

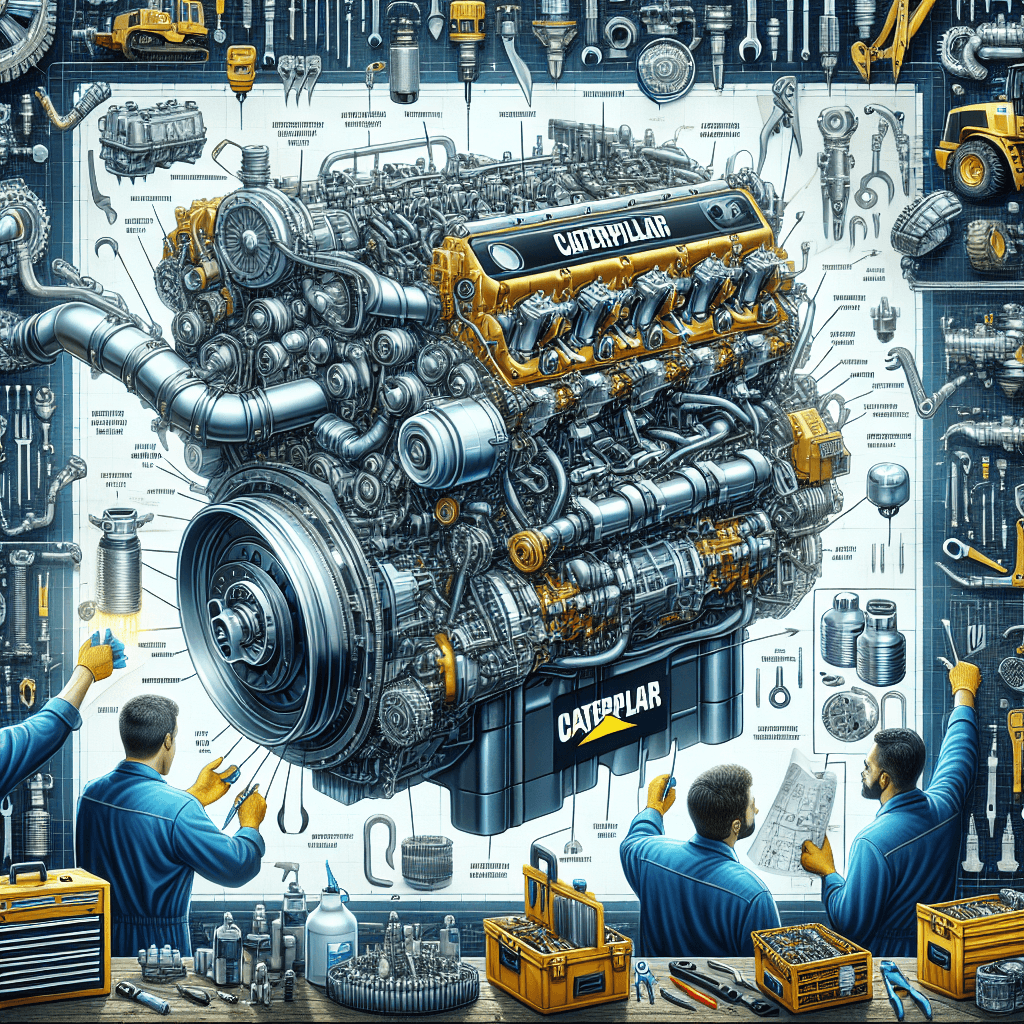

Understanding how every component fits together is crucial when working with Caterpillar equipment. The parts book manual provides detailed descriptions and exploded diagrams that illustrate the assembly process, making it easier for users to see how each component interacts with the others. This understanding is essential for ensuring that the equipment operates smoothly and efficiently.

One of the key benefits of understanding how components fit together is that it helps prevent assembly errors. By following the detailed descriptions and diagrams in the manual, users can ensure that each part is installed correctly. This reduces the likelihood of issues arising from improper assembly, which can lead to costly downtime and repairs.

Another benefit is that it makes troubleshooting easier. When a machine is not functioning correctly, understanding how the components fit together can help users identify the source of the problem. By visually tracing the assembly and checking each part, users can pinpoint potential issues and take corrective action. This can save time and reduce the need for trial-and-error troubleshooting.

Understanding how components fit together also helps with maintenance. The manual includes detailed maintenance schedules and procedures, ensuring that users can keep their equipment in top condition. By following these guidelines and understanding how each component fits into the larger assembly, users can perform maintenance tasks more effectively and extend the life of their equipment.

For those who need to order replacement parts, understanding how components fit together is essential. The manual includes detailed ordering information, including part numbers, descriptions, and pricing information. By understanding the assembly process and knowing which parts are needed, users can ensure that they order the correct components and avoid delays in repairs.

Finally, understanding how components fit together is beneficial for training purposes. The detailed descriptions and exploded diagrams in the manual provide a valuable reference for new employees or users who are not familiar with a particular piece of equipment. By studying the manual and learning how each component interacts with the others, users can gain a deeper understanding of the equipment and become more proficient in its operation and maintenance.

In summary, understanding how every component fits together is essential when working with Caterpillar equipment. The parts book manual provides the detailed information and visual guides needed to ensure proper assembly, troubleshooting, maintenance, and training. By taking the time to study the manual and understand the assembly process, users can ensure that their equipment operates smoothly and efficiently.

Navigating the Comprehensive Parts Book Manual

Navigating the comprehensive Caterpillar parts book manual may seem daunting at first, given the sheer volume of information it contains. However, the manual is designed to be user-friendly, with a logical organization and clear indexing that make it easy to find the information you need. Each section of the manual is dedicated to a specific part of the machine, allowing users to quickly locate the relevant information.

The manual typically begins with an overview section that provides general information about the machine, including its specifications and capabilities. This section serves as an introduction and provides context for the more detailed information that follows. It is a good starting point for users who are new to the equipment or who need a refresher on its features.

Following the overview, the manual is divided into sections based on the different systems and components of the machine. Each section includes detailed descriptions, exploded diagrams, and ordering information for the parts within that system. The sections are typically organized in a logical order, starting with the major systems such as the engine and transmission, and then moving on to smaller components.

One of the key features that make the manual easy to navigate is its use of indexing and cross-referencing. Each part is assigned a unique identifier, which is used consistently throughout the manual. This makes it easy to cross-reference parts and find the information you need. The manual also includes a comprehensive index at the end, which allows users to quickly locate specific parts or sections.

For those who prefer digital resources, many Caterpillar parts book manuals are available online. Websites like Equip-Manual provide access to digital versions of the manuals, which can be searched and navigated more easily than their printed counterparts. This can be especially useful for users who need to find information quickly or who prefer to work with digital documents.

In addition to the manual itself, Caterpillar provides a range of support resources to help users navigate the manual and find the information they need. This includes online tutorials, customer support, and authorized dealers who can provide assistance. By taking advantage of these resources, users can ensure that they are using the manual effectively and getting the most out of their equipment.

Overall, navigating the comprehensive Caterpillar parts book manual is made easier by its logical organization, clear indexing, and available support resources. Whether you are using a printed manual or a digital version, the detailed information and visual guides within the manual provide everything you need to maintain and repair your Caterpillar equipment.

The Caterpillar parts book manual is an indispensable tool for anyone who owns or operates Caterpillar equipment. It provides a detailed breakdown of every component, illustrated with exploded diagrams that make assembly and maintenance straightforward. Understanding how each component fits together ensures that the machinery operates smoothly and efficiently, while the comprehensive and user-friendly design of the manual makes navigation simple. For those who prefer digital resources, websites like Equip-Manual offer easy access to these valuable documents. By leveraging the detailed information and visual guides provided in the Caterpillar parts book manual, users can ensure that their equipment remains in top condition, reducing downtime and extending the life of their machinery.