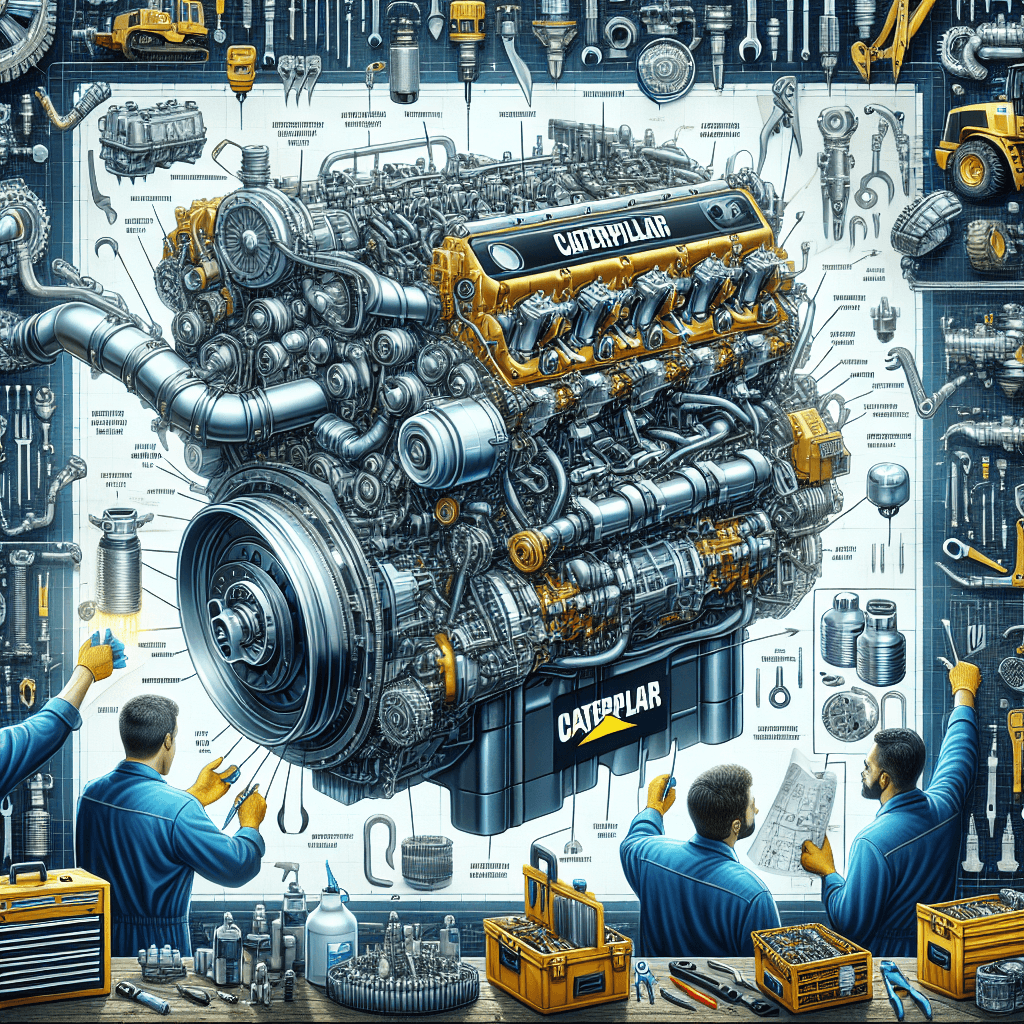

Caterpillar engines are renowned for their durability and performance, powering a wide range of heavy machinery used in industries such as construction, mining, and transportation. However, like all mechanical systems, they require regular maintenance, repairs, and occasional overhauls to ensure optimal performance and longevity. Repairing and overhauling these engines is a complex task that necessitates adherence to the manufacturer’s guidelines. This article delves into the importance of manufacturer guidance in engine repairs, outlines key steps in overhauling Caterpillar engines, discusses recommended tools and resources, and explores common challenges and solutions in the engine overhaul process.

Importance of Manufacturer Guidance in Engine Repairs

Repairing heavy-duty engines like those produced by Caterpillar is not a task to be taken lightly. The manufacturer’s guidance is critical for several reasons. First and foremost, these guidelines ensure that the repairs are performed correctly, maintaining the engine’s integrity and performance. Caterpillar provides detailed instructions on how each component should be handled, which is crucial for avoiding mistakes that could lead to further damage or reduced engine efficiency.

Another significant aspect is safety. Caterpillar engines are complex and powerful machines, and improper handling can result in serious injuries. Manufacturer guidelines include safety protocols that must be followed to protect both the technician and the machinery. These safety measures are based on extensive testing and real-world experience, making them invaluable for anyone undertaking engine repairs.

Adhering to manufacturer guidelines also ensures that the warranty remains valid. Many Caterpillar engines come with warranties that can be voided if unauthorized repairs are performed. By following the prescribed procedures and using recommended parts, technicians can avoid this risk, ensuring that the engine remains covered under warranty.

Moreover, manufacturer guidance often includes updates and revisions based on the latest research and technological advancements. By staying up-to-date with these recommendations, technicians can make use of the most recent improvements and fixes, thereby enhancing the engine’s performance and reliability.

Cost efficiency is another factor. While it might seem cheaper to bypass manufacturer guidelines, doing so can lead to costly mistakes. Incorrect repairs can result in further damage, necessitating additional work and parts. Following the manufacturer’s guidance helps avoid these pitfalls, ultimately saving time and money.

Finally, using manufacturer guidance fosters consistency. Caterpillar engines are used in a variety of applications, and consistent repair practices ensure that all engines perform reliably, regardless of where they are used or who performs the repairs. This consistency is vital for industries that rely on these engines for their operations.

Key Steps in Overhauling Caterpillar Engines

Overhauling a Caterpillar engine is an intricate process that involves several key steps. The first step is a thorough inspection and diagnosis. This involves checking the engine for any signs of wear and tear, leaks, or other issues that may affect its performance. Diagnostic tools and software recommended by Caterpillar can be used to identify any underlying problems that need to be addressed.

Once the diagnosis is complete, the engine is disassembled. This step requires meticulous attention to detail, as each component must be carefully removed and documented. Using the manufacturer’s guidelines ensures that the disassembly process is done correctly, preventing damage to the parts and making it easier to reassemble the engine later.

Cleaning is the next critical step. All components must be thoroughly cleaned to remove any dirt, oil, or debris. This is essential for ensuring that the engine operates smoothly and efficiently once it is reassembled. Caterpillar provides specific cleaning solutions and methods for different parts, which should be followed to achieve the best results.

After cleaning, the components are inspected for damage and wear. Any parts that are worn out or damaged beyond repair must be replaced. Caterpillar’s guidelines include specifications for acceptable wear limits and recommendations for replacement parts. Using genuine Caterpillar parts is crucial for maintaining the engine’s performance and longevity.

Reassembly is the next step, and it requires as much attention to detail as the disassembly process. Each component must be reinstalled in the correct order and torqued to the specifications provided by Caterpillar. This ensures that the engine operates as intended and prevents issues such as leaks or mechanical failures.

The final step is testing. Once the engine is reassembled, it must be tested to ensure that it is functioning correctly. This involves running the engine under various conditions and checking for any issues. Caterpillar provides detailed testing procedures that should be followed to verify the engine’s performance and reliability.

Tools and Resources Recommended by Caterpillar

Caterpillar provides a comprehensive list of tools and resources that are essential for repairing and overhauling their engines. One of the most important resources is the service manual, which provides detailed instructions for every aspect of engine maintenance and repair. These manuals can be accessed through Equip-Manual, which offers a wide range of Caterpillar service manuals.

Diagnostic tools are also crucial. Caterpillar engines are equipped with advanced electronic control systems that require specialized diagnostic equipment to troubleshoot. Caterpillar recommends using their proprietary diagnostic software and tools, which are designed to interface seamlessly with their engines and provide accurate diagnostic information.

Specialized tools are another key resource. Caterpillar engines often require tools that are specifically designed for their unique components. These tools ensure that repairs are performed correctly and efficiently. Using the recommended tools also helps prevent damage to the engine parts, which can occur if improper tools are used.

In addition to tools, Caterpillar offers training resources for technicians. These training programs cover everything from basic maintenance to advanced repair techniques. By participating in these programs, technicians can ensure that they are fully equipped to handle any issues that may arise during the repair process. Information about these training programs can also be found on Equip-Manual.

Caterpillar also provides a range of parts and consumables that are specifically designed for their engines. Using genuine Caterpillar parts is essential for maintaining the engine’s performance and reliability. These parts are designed to meet the exact specifications of the original components, ensuring a perfect fit and optimal performance.

Finally, Caterpillar offers technical support to assist with any issues that may arise during the repair process. This support can be invaluable, particularly for complex repairs or unusual problems. Technicians can access this support through Caterpillar’s service network or online resources like Equip-Manual, which provides access to a wealth of technical information and support.

Common Challenges and Solutions in Engine Overhaul

Overhauling a Caterpillar engine presents several challenges, but with the right knowledge and resources, these can be effectively managed. One common challenge is diagnosing the root cause of engine problems. While diagnostic tools can help, interpreting the data correctly requires experience and expertise. Technicians should rely on Caterpillar’s diagnostic guidelines and training to accurately identify and address issues.

Another challenge is sourcing the right parts. Using non-genuine parts can lead to compatibility issues and reduced engine performance. Caterpillar engines are designed to work with specific components, and using the wrong parts can cause significant problems. To avoid this, technicians should always use genuine Caterpillar parts, which can be sourced through authorized dealers or resources like Equip-Manual.

Reassembly errors are also a common issue. The complexity of Caterpillar engines means that reassembling them incorrectly can lead to a host of problems, from minor leaks to major mechanical failures. Following the manufacturer’s reassembly guidelines meticulously is essential. This includes using the correct torque settings and ensuring that all components are installed in the correct order.

Dealing with wear and tear is another challenge. Over time, engine components can wear out, affecting performance and reliability. Identifying which parts need to be replaced and which can be refurbished requires a keen eye and knowledge of Caterpillar’s wear specifications. Technicians should refer to the service manuals and use the recommended inspection tools to make these determinations.

Ensuring that the engine is properly tested after an overhaul is also critical. Skipping or inadequately performing this step can result in undetected issues that could cause the engine to fail prematurely. Caterpillar provides detailed testing procedures that should be followed to ensure that the engine is operating correctly before it is returned to service.

Finally, keeping up with the latest updates and recommendations from Caterpillar can be challenging but is essential for effective engine maintenance and repair. Caterpillar continually updates their guidelines based on new research and technological advancements. Technicians should regularly consult resources like Equip-Manual to stay informed about the latest recommendations and best practices.

Repairing and overhauling Caterpillar engines is a complex process that requires careful attention to detail and strict adherence to the manufacturer’s guidelines. By following Caterpillar’s recommendations, technicians can ensure that repairs are performed safely, correctly, and efficiently, maintaining the engine’s performance and reliability. Utilizing the right tools, parts, and resources, such as those available through Equip-Manual, is essential for successful engine maintenance and overhaul. Despite the challenges, with the right knowledge and support, technicians can effectively manage the repair and overhaul processes, ensuring that Caterpillar engines continue to power their machinery reliably for years to come.